TECHNOLOGY

Three dimensional ship design

Advanced software TRIBON M3 is used for 3d ship design. After the hull design and overall arrangement, coordination and balance of the whole ship by 3d ship design software TRIBON M3, reasonable division is made according to stages (embedded, preloaded, total section and region), and relevant production drawings are produced to meet requirements of production and construction.

Advanced vibration and noise reduction technology

The company’s vibration and noise analysis:1.Active noise cancellation technology, namely noise source reduction technology, is implemented by equipment selection and optimization of installation procedure; 2. Passive noise cancellation technology, namely, it is realized through the research and development of vibration isolation and noise reduction technology of superstructure. When the experimental ship or vessel and other large and medium-sized military auxiliary ship is in the missions at sea, it has such functions as communications for surveying and mapping, as well as the sea research, so the lower the noise from the ship itself is, the clearer feedback signal for collecting information from ocean is. On the other hand, if the ships noise surpassed the requirements, it is unable to complete the corresponding ocean information collection task, even, severe situation can directly lead to failure of task. In the process of ship construction, vibration reduction and noise reduction control technology is mainly adopted to reduce the noise of ship navigation and meet the requirements of noise index, so as to achieve the main mission of experimental ship or surveying vessel.

The company has mastered the vibration and noise reduction control technology by tackling key problems and studying, coupled with formed a complete set of guidance documents and procedures for the implementation of vibration and noise cancellation. Therefore,the noise index of the ship can be controlled well. The main technical features are as follows: 1. 3D modeling to encrypt value points is used to make hull lines smoother and resistance smaller. 2. The vibration noise analysis is carried out to improve the structural strength of stress concentration points. 3. The equipment installation and pipeline layout for noise reduction design is guided. 4. Noise reduction can be achieved by improving internal installation and laying damping materials in key parts. 5. It is developed to the guiding technology of vibration and noise cancellation. 6. The on-site fine vibration reduction and noise reduction management mechanism is implemented.

At present, this technology is not only successfully adopted in all types of ships with noise index requirements, but also has realized its value in the company’s series of Marine engineering ships, reaching the common technical requirements of military and civilian use. It is one of the important technologies for our company to build military ships. The 636 ocean comprehensive surveying vessel built by our company is known as “ocean black hole” by foreign websites, because its most outstanding performance is silence, even more than many anti-submarine ships. It is published a paper for this technology, the company applied for the “cabin noise analysis and noise cancellation technology research” tech item.

-

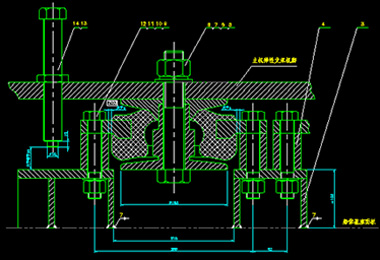

Shock absorber schematic

Shock absorber schematic -

Host vibration isolation

Host vibration isolation -

Application of sound insulating materials of cabin

Application of sound insulating materials of cabin

Advanced precision installation and debugging technology of long shaft multi-propeller propulsion system

According to technical research, in the first place, the internal field preloading scheme of shaft tube bearing is adopted, and precision control technology is used to ensure the installation accuracy by moving forward the process. Secondly, by the means of shafting lighting and special tooling research and development, the liner is lifted and transported to the berth as a whole. According to epoxy casting or efficient boring plan, the installation accuracy is effectively controlled and the installation cycle of slipway is shortened. Finally, reasonable shafting alignment method and debugging program is adopted to master shafting installation and system debugging technology. Two copies of technical documents: principles and procedures for the installation of part of the tail-tilting longshafting slipway, principles and procedures for the installation of the underwater part of the tail-tilting longshafting; And two patents: “a ship propeller hoisting device _zl201420211186.0”, “a ship boring device shaft positioning device _zl201620382705.9”. One published paper: “research on reasonable alignment process of Marine engineering captain shaft system” (journal of mechanical and electrical equipment, vol. 34, no. 279)

-

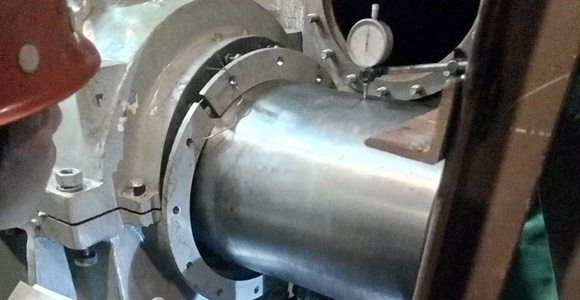

Measurement of bearing load jacking

Measurement of bearing load jacking -

6500HP long shaft system installation

6500HP long shaft system installation

Corrosion protection technology for metal materials

Painting construction capability. Internal field equipment of painting, plant technical parameters and capacity: sandblasting capacity: steel surface treatment grade reaches Sa2.5, roughness is between 30~75um, block typical size is 15M×12M×5M, abnormal block is 15M×12M×11M. Average daily processing capacity of sand blasting: 4000m2(one spray and four coatings), maximum daily processing capacity of paint spraying: 5000m2(one spray and four coatings), annual processing capacity: 1.2 million m2(one spray and four coatings). In the painting field, high-altitude operation vehicle, vacuum sand suction machine and four seasons dehumidifier are equipped to meet the project all-weather painting construction. It meets the requirements of environmental protection, and implement the “air pollutant emissions” (GB16297-1996) standards. With mature anticorrosion technology of metal materials and advanced detection instruments, company has accumulated rich practical experience in phosphating, passivating and galvanizing pickling, especially in the fields of sacrificial anode and electrochemical corrosion technology.

-

Anticorrosive paint of the bow block

Anticorrosive paint of the bow block -

Anti-corrosion zinc plate

Anti-corrosion zinc plate