NEWS

The shipway construction node of the 8000 DWT small general cargo ship is successfully concluded

![]() TIME:2020-11-07 08:54

TIME:2020-11-07 08:54![]() AUTHOR:Wuhu Shipyard

AUTHOR:Wuhu Shipyard ![]() VIEWS:0

VIEWS:0

On November 6th, the No 10 8000DWT series built by Wuhu Shipyard Co., Ltd. for India's JSW Steel Co., Ltd.-the 80009 ship "JSW RATANGAD" was successfully launched. The 80009 ship started the construction of the slipway on June 19, and was launched safely and smoothly on November 6, and entered the mooring test phase. This marked the successful completion of the construction of the entire slipway for the 10 small general cargo ships in this batch. Indian JSW Steel Co., Ltd. Mr. Sun Tie and other resident representatives, Indian Classification Society Mr. He Zhendong and other resident managers and surveyors, company deputy general managers Wang Ruhua, Du Chengchang and other leaders attended the launching ceremony.

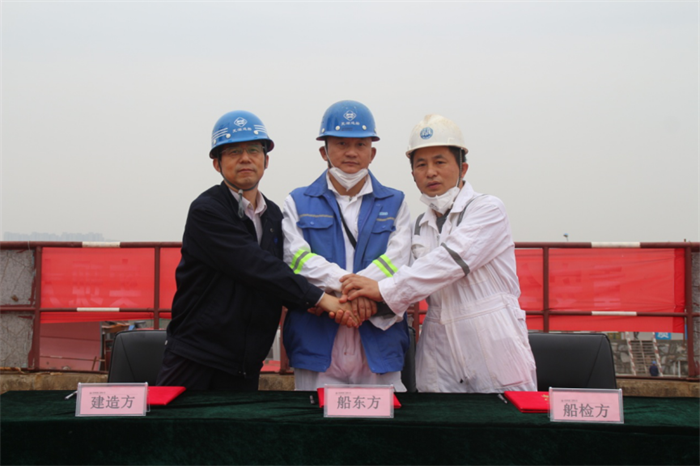

(Ship Owner, ship inspector and company leaders have participated in the launching ceremony)

During the construction of the ship, the ship set the first place among three slipways, and for the first time realized the construction of half a ship's ring section, completed the formation of the cargo hold area of the hull No. 1, and carried it on the stern to realize the whole ship through. The first 8,000-ton ship to practice the integration of shell and outfitting coating, finished the outer panel coating finish spraying on the berth, and realized the installation of the electrical connection and conduction system on the berth for the first time, and the navigation signal lights were completely illuminated. On September 21st, the 80008 ship built on the stern of the 80009 ship with the slipway was launched safely and smoothly. The ship was built on the slipway at an accelerated pace. The people of Wuchuan used their wisdom and wisdom to maximize the utilization rate of a slipway. With 80009-327P and S/207 cargo hold ring-shaped general section to the stern, continuous loading and hoisting can perfectly solve the problems of high water level during flood season and insufficient space for two ships built on the same platform.

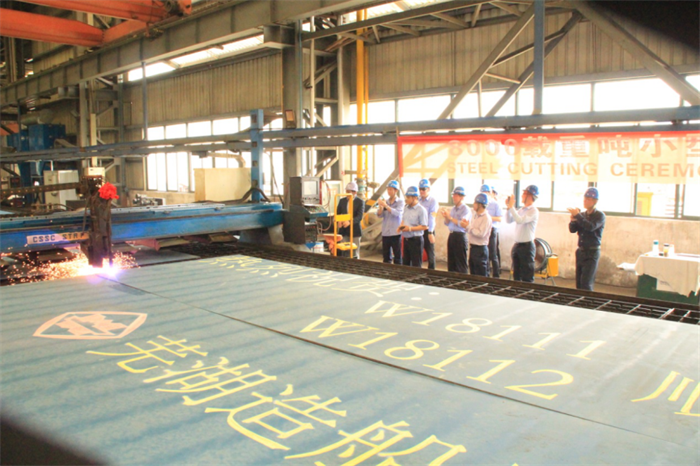

(This picture shows the start of construction of the first 8000 DWT ship on June 28, 2019)

(This picture shows the launching ceremony of the ship 80009 "JSW RATANGAD" on June 19, 2020)

It is understood that the No 10 8000 DWT small general cargo ships built by the company for Indian shipowners began mass production on June 28, 2019. On January 21, 2020, the first 8,000DWT ship was launched safely and smoothly on November 6. The day ushered in the safe and smooth launching of the 8,000DWT final ship. From the severe winter to the late autumn, a large number of Wuchuan people’s efforts were collected during the construction process. From the first PSPC subsection sand washing report to the last hoisting and erection, we remember it again, the hard work and effort during this period is also worthwhile. Among them, the 80010 ship has completed the safe and smooth launch in only 55 days on the berth cycle, and it is also the 8000 DWT series ship with the shortest berth cycle.

The ship has a total length of 122 meters, a depth of 7.2 meters, and a width of 20 meters. The whole ship is designed as a double-bottom structure. It adopts conventional power system, driven by diesel engine, dual-engine dual-propeller propulsion, equipped with dual rudder system, equipped with 2 cargo compartments, hydraulic foldable hatch cover, and is classified into Indian Bureau of Shipping. It is suitable for the transportation of bulk cargo within India's domestic offshore navigation area.

(80009 ship "JSW RATANGAD" splits into the Yangtze River)

(Mr. Sun Tie of JSW, Mr. He Zhendong of Indian Register of Shipping, and Mr. Wang Ruhua, Deputy General Manager of the company jointly signed the launch)

At present, most of the ship orders held by the company are high-end ships, which have the characteristics of high technical difficulty, high quality requirements, and difficult cycle control. However, "Wuhu Shipyard man" are confident to turn them into fine products and realize the company's " The transition from "following" to "leading". The fourth quarter of 2020 activities are in full swing, regardless of the pre-preparation, design, production and other aspects, all departments are also working overtime for the decisive victory in 2020 and persevere in 2020. On the 2020 production and operation goals, we adhere to the concept that completing production tasks is the last word. The production department implements a two-shift 24-hour operation, strives to take back the time affected by the epidemic and the flood season, and strives to achieve the 2020 development and operation goals.