NEWS

Major Breakthrough: Wuhu Shipyard Successfully Achieves Half-Hull Transfer on Inclined Shipway

![]() TIME:2026-01-23 10:55

TIME:2026-01-23 10:55![]() AUTHOR:Wuhu Shipyard

AUTHOR:Wuhu Shipyard ![]() VIEWS:0

VIEWS:0

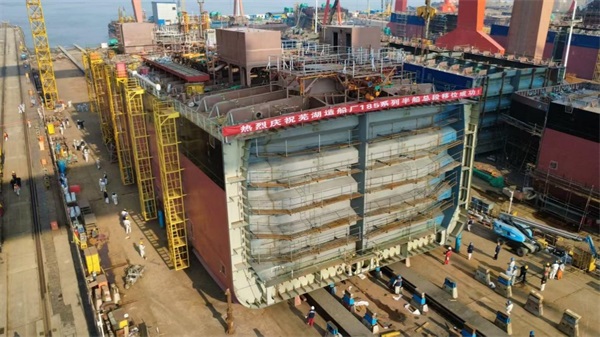

On January 23, Wuhu Shipyard successfully completed the transfer of a half-hull block weighing over 2,100 metric tons for the chemical tanker 18514 from its 18,500-ton series on the No. 2 inclined shipway. This marks the first time in China that a self-propelled modular transporter (SPMT) has been utilized to accomplish half-hull relocation on an inclined shipway, enabling the application of tandem construction methods on such platforms. The achievement represents a groundbreaking milestone in the shipyard’s modular construction technology.

During the transfer operation, the 2,100-ton half-hull block consisted of three large ring-shaped assemblies, comprising a total of 45 sub-sections, and was precisely maneuvered by a synchronized system of 12 self-propelled modular transporters (SPMTs). From initiation to final positioning, the block moved steadily along the inclined shipway over a distance of 125 meters, completing the entire process in just 45 minutes and achieving zero-error precision placement. The shipyard broke through the technical constraints of inclined shipway transfers with millimeter-level accuracy—a breakthrough that was anything but accidental. Rather, it represents the culmination of Wuhu Shipyard's century-long expertise and relentless progress: from the initial attempt of the "one-and-a-half hull construction method" in August 2025, to the leap in efficiency achieved with module transporter-based block transfers in October of the same year, and now to the successful application of the "tandem construction method on inclined shipways." Each technological iteration embodies the relentless pursuit of excellence by the team at Wuhu Shipyard.

Faced with the triple challenges of heavy block tonnage, extended transfer distance, and stringent precision control, the outfitting workshop and the process engineering department worked in close collaboration to systematically deconstruct the half-hull construction process into standardized, manageable, and refined procedural units. This provided a solid technical foundation for the high-precision transfer operation. Under the dual pressures of severe winter conditions and a tight schedule, the team worked tirelessly for three consecutive days to turn the “impossible” into a first-attempt success. Not only did they overcome the difficulties associated with the long-distance transfer and high-precision positioning of large ring-shaped blocks, but they also pioneered a new process route for transporting chemical tanker half-hull blocks using coordinated SPMTs. This has established a replicable and scalable “Wuhu Shipyard Solution” for the construction of chemical tankers and other vessel types, translating technological breakthroughs into tangible efficiency gains and showcasing Wuhu Shipyard’s core competitiveness in transitioning from “scale expansion” to “quality-driven growth.”

“Quantitative Accumulation Drives Qualitative Change, Innovation Fuels Growth.” The application of the tandem construction method on inclined shipways represents a deep implementation of the “trading space for time” philosophy. By efficiently maximizing the utilization of shipway resources, this approach achieves optimal output within limited production factors. It upgrades the traditional “one hull on shipway + one hull on platform” production model to a highly efficient “1.5 hulls on shipway + 1.5 hulls on platform” synchronous construction mode. As a result, the ship construction cycle has been significantly shortened, and pre-launch completeness has been substantially improved. Within this efficient system, the utilization area of the shipway has increased from the previous 65% to over 95%, while overall shipway utilization and construction turnover rates have improved by more than 20%. Furthermore, through process reengineering and task decomposition, the tandem construction method on inclined shipways has effectively optimized workforce allocation, reduced excessive labor concentration, and significantly enhanced on-site operational safety as well as the quality of modular unit construction. This drives production tasks toward a more balanced, rhythm-based, and efficient workflow.

With the tide at its full and countless sails already ahead, it is time to set forth with the wind and break through the waves. The success of this half-hull block transfer marks a significant breakthrough in process technology and vividly embodies the corporate spirit of Wuhu Shipyard—“Unity, Endeavor, Pragmatism, Innovation, Excellence, and Efficiency.” Moving forward, Wuhu Shipyard will continue to refine, standardize, and strengthen the application of the tandem construction method on inclined shipways, striving with full momentum toward the goal of “commissioning-ready upon launching.” This will ultimately achieve an efficient construction framework where “installation is completed on the shipway and testing is conducted at the dock,” writing new legends for “Intelligent Manufacturing in China.”