NEWS

New Production Breakthrough! Engine Room Bottom Module for Hull 18525 Successfully Delivered

![]() TIME:2025-12-31 10:43

TIME:2025-12-31 10:43![]() AUTHOR:Wuhu Shipyard

AUTHOR:Wuhu Shipyard ![]() VIEWS:0

VIEWS:0

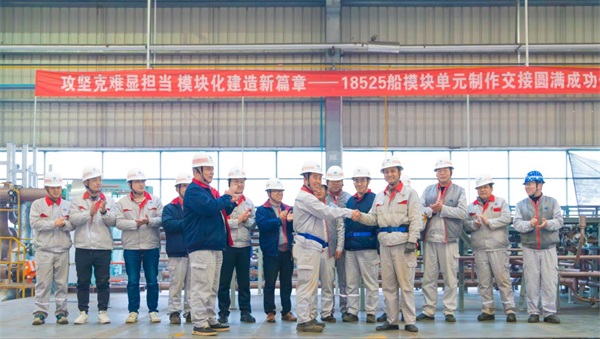

On December 30, a grand delivery ceremony was held in the module workshop for the engine room bottom module of Hull 18525. The event was attended by the company's General Manager, the Director of the Production and Operations Center, along with leaders and key technical personnel from relevant departments.

Guided by the General Manager, the team performed a thorough final inspection of the module. All parameters met construction standards, and the module was officially accepted. During the inspection, the General Manager praised the project team's determined efforts in overcoming challenges. He highlighted that the success of this modular construction project stemmed from a process innovation principle of "simplifying complex operations and creating platforms for underwater work." This approach reduced the time required for individual tasks to about one-third of the traditional duration, significantly shortening the overall occupancy time of the building berth and dock. Consequently, it enhanced production efficiency while strengthening inherent safety levels and cost-control capabilities.

The construction of this engine room bottom module embodies the advanced philosophy of "building ships like building cars" through modular methods, effectively addressing limitations of traditional shipbuilding. The module was manufactured in strict compliance with the standards set forth in the "Guidance for Outfitting Unit and Module Design and Manufacturing." It integrates the piping, electrical, steel outfitting, and equipment for the engine room bottom into a single, pre-fabricated unit. This achieves the goal of "workshop prefabrication, integrated lifting, and efficient berth assembly." This transformation shifts shipbuilding away from dependence on a single berth to a production model capable of parallel work on different sections and modules, greatly reducing build times and improving both resource efficiency and overall delivery capacity.

The delivery of this workshop module establishes a replicable and scalable template for standardized modular construction. It provides valuable experience and a clear model for advancing the unitization and modularization of future vessel designs. The company will further enhance its front-end engineering design capabilities, continuously expand the scope and standardization of unit modules, and inject stronger momentum into the profound transformation of its construction methodology.

Contributed by: Wang Yizi, Production Management Department; Chen Zidan, Party-Mass Work Department

Edited by: Shui Qing