NEWS

The company successfully passed the annual supervision and audit of ISO9001 quality management system

![]() TIME:2019-08-29 08:50

TIME:2019-08-29 08:50![]() AUTHOR:Wuhu Shipyard

AUTHOR:Wuhu Shipyard ![]() VIEWS:0

VIEWS:0

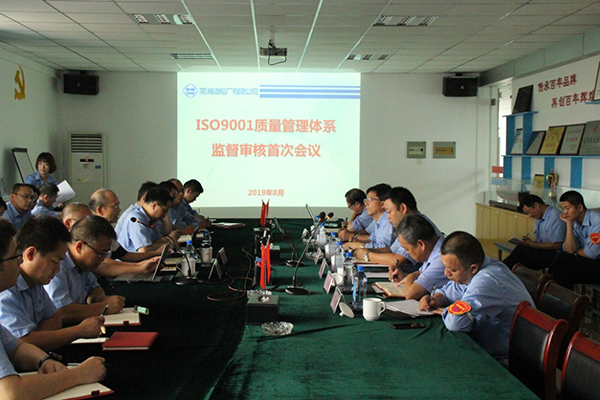

From August 29th to 30th, experts of the China Classification Society visited Wuhu shipyard to conduct the first annual supervision and audit after the revision of the ISO9001 quality management system. Zhang Zhao - general manager of the company, directors of the centers, module managers and related personnel attended the first and last meetings, which were held in the conference room 303 of No 1 building.

At the meeting, General Manager Zhang Zhao introduced the company's development strategy, production and operation objectives and the current operation of the company's quality management system to the audit team experts and asked for a strict review and suggestions for improving. Mr. Zhang stressed that all levels of the company should take the supervision and audit of the quality management system as an opportunity to further implement the relevant requirements of the quality management system to the actual work, internalize the company's quality policy and quality management principles, externalize in behaviour and continue to improve the core competitiveness of the company, thus promoting the company's transformation and upgrading, innovation and development, and striving to provide customers with satisfactory products.

This audit is mainly based on ISO9001-2015, GB/T19001-2016 standards and the company's quality management system manual, program files, and third-level documents. The audit team has reviewed the company's technical quality center, production and operation center, marketing center, Party and integrated management center, cost center and other departments, involving product design, development, production, inspection and service.

At the last meeting, the audit team affirmed the company's quality management work over the past year. The overall management level of the company has improved significantly compared with the previous year, and the audit team announced that the company successfully passed the annual supervision and audit of the quality management system. At the same time, the audit team proposed improvement items and suggestions for related problems in the operation of the system, such as qualified supplier management, drawing management, contract review, after-sales service, customer satisfaction, human resource management, training, and welding control.

Finally, the company's leaders made relevant requirements that the relevant departments must rectify the problems raised by the audit team as soon as possible and must make continuous improvements.

This audit not only reviewed the ISO9001-2015 and GB/T19001-2016 implementation, but also played a positive role in promoting the company's quality management, and laid the foundation for the company's follow-up product market.